Editor's Note: This is the last feature that Tiger McKee wrote for the wires. It appeared in our April 13, 2023 edition. Seeing the new S&W J-frame Ultimate Carry guns makes it seem that Tiger's spirit is moving small revolver manufacturing -

A couple of features ago, I talked about the underrated S&W “J” frame. While they have many advantages, one of the downsides is the anemic fixed front sight. However, there is a cure for this, and it’s an easy D.I.Y. project.

There are J frames that come with pinned front sights, which are fairly easy to replace. Remove the pin and pull out the old sight. Position the new sight, then using the existing holes in the barrel, drill a hole in the new sight base for the pin. (It’s best to drill from both sides to the center.). Install the sight and pin, using a little thread sealer to ensure placement.

Fixed sight pistols – the sight is part of the barrel – are a little more difficult. XS Sights offers a replacement sight, their “Big Dot” tritium sight, but installation is a little more involved. Since the factory front sight is thin and difficult to see, especially for defensive work and low-light situations, replacing it can be a smart move.

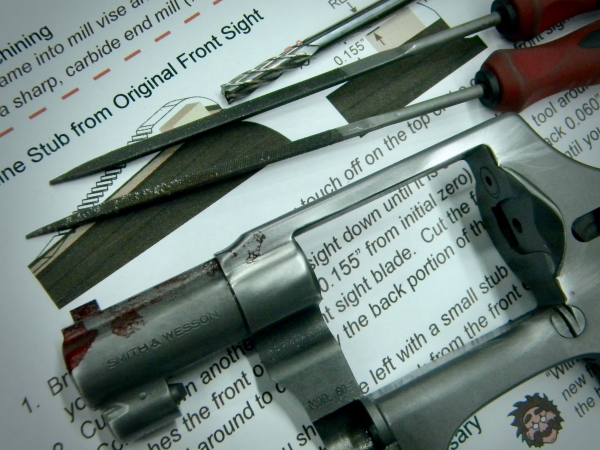

Installation requires cutting down the existing front sight to a mounting nub. The XS sight uses epoxy over the top of that nub. There are two ways of removing material from the front sight. Obviously, a milling machine is the best way; it’s easy and consistent. This is just one of about a million reasons to have a milling machine in your shop. Not a full-size, industrial type mill, but one of the smaller table or bench-top mills. These miniature versions of the “real thing” are perfect for sight work, modifying small pieces or machining a custom part from a block of metal. There is a learning curve but if you have a mechanical inclination and can perform a little math the only limit will be your imagination.

Cutting down the front sight can also be done by hand, using files. This is slower than using a milling machine, and requires patience. This is the way I did it prior to getting a mill. The old rule of measure twice and cut once definitely applies. Remember, it’s always easy to remove more material, but it's a real pain to correct a cut that was too large or deep.

To keep you from having to start cutting from scratch, XS supplies complete info on how to install their sights on their website. (Here are instructions on various type S&W J frames - https://xssights.com/content/Install%20Instructions/SW%20J-Frame%20Fixed%20Installation.pdf .)

The XS tritium sights for J frames are available in both their “Big” dot and “Standard” dot versions, as well as options for Ruger and Taurus revolvers. The older I get, and the more my eyes age, the more I appreciate the “Big” dot sight. It’s quick to acquire under all light conditions and still provides the accuracy needed for small targets and longer distance shots.

Along with installing the XS sight on the front it’s a good idea to open up the rear sight from the factory square notch to a “U” shape. Again, this can be done on a milling machine or – I find this easier and quicker – just using a round file of the appropriate size.

J frames “rock.” They’re small and lightweight; easy to conceal and carry. They are also way more accurate than most people can shoot them. They are ideal for defensive carry or as a secondary weapon - as long as you’re willing to invest in training and commit to regular practice. After a couple of modifications – like an XS front sight – they’re almost “perfect.”

Tiger McKee is director of Shootrite Firearms Academy. He is the author of The Book of Two Guns, AR-15 Skills and Drills, has a regular column in American Handgunner and makes some cool knives and custom revolvers. www.shootrite.org or visit Shootrite’s Facebook page for other details.